Your marketing team wants “clean-label.” R&D wants performance. Your job? Make sure nothing jeopardizes safety, traceability, or compliance. If you’re in QA, regulatory, or food safety, this is the clean-label sprinkle sourcing guide you’ve been waiting for.

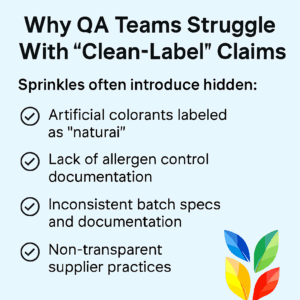

Why QA Teams Struggle With “Clean-Label” Claims

The term “clean-label” has no regulatory definition—yet it drives consumer perception and marketing language. QA teams are left translating ambiguous claims into actual compliance and product integrity. This is especially risky when it comes to visually impactful inclusions like sprinkles.

Sprinkles often introduce hidden risks:

- Artificial colorants labeled as “natural”

- Lack of allergen control documentation

- Inconsistent batch specs and documentation

- Non-transparent supplier practices

When you’re tasked with validating label claims and preventing recalls, these gray areas are unacceptable.

What Clean-Label Means for Regulatory Teams

For QA and regulatory professionals, “clean-label” must be translated into real compliance terms:

- No artificial colors or flavors

- Verified non-GMO status

- Allergen-free (or full allergen disclosure)

- Vegan, Kosher, or Halal certs if claimed

- GRAS status or EU equivalent safety listing

FoodGrid’s clean-label sprinkles are sourced from vetted manufacturers who meet global food safety and documentation standards.

See how we simplify regulatory screening →

Top Compliance Risks in Sprinkle Sourcing

1. Undisclosed Synthetic Additives

Some suppliers may use synthetic carriers or coating agents while advertising the base pigment (e.g., beet juice or spirulina) as “natural.”

🔍 What to ask for: Full ingredient disclosure including minor components, carriers, and anti-caking agents.

2. Color Additives and Labeling Laws

FDA and EFSA maintain strict lists of permitted natural colorants. A pigment approved in one market may be banned or require specific labeling in another.

🔍 What to verify: Global compliance status and region-specific labeling requirements.

3. Allergen Cross-Contamination

Sprinkles made in shared facilities may have exposure to peanuts, soy, or dairy, even if not listed on the label.

🔍 What to require: Third-party allergen testing, updated food safety certifications (SQF, BRC, etc.).

4. Inconsistent Specs and COAs

Batch variation can throw off QA testing and result in out-of-spec finished goods.

🔍 What to demand: Batch-level COAs and spec conformity data.

5. Unverifiable Claims (Vegan, Kosher, Non-GMO)

If your marketing team is touting “vegan” or “non-GMO,” you need documentation that holds up to regulatory and retailer audits.

🔍 What to confirm: Valid certs from recognized authorities like NSF, OU, and Non-GMO Project.

FoodGrid’s QA-First Approach to Ingredient Discovery

We designed FoodGrid with QA and compliance officers in mind. Our platform makes it easy to:

- Pre-filter sprinkles by regulatory attributes (non-GMO, vegan, kosher, allergen-free)

- Access technical spec sheets and COAs before sampling

- Work only with pre-vetted, documentation-ready suppliers

- Request compliance data by lot or batch

Built for Audits, Not Just Aesthetics

Aesthetic inclusions like sprinkles shouldn’t increase your regulatory exposure. With FoodGrid sprinkles, you get:

- Full label transparency

- Access to current safety certifications

- Allergen statements with batch traceability

- Ingredient breakdowns that pass international scrutiny

Whether your next audit is from the FDA, a retailer, or a third-party certifier, you can be confident in what you’re sourcing.

Explore our clean-label sprinkle line →

Case Use: Compliance Challenges Solved

Case 1: U.S. Food Brand Sourcing for EU Launch

A QA Director sourcing sprinkles for a clean-label ice cream line flagged a “natural blue” pigment as non-compliant in the EU. FoodGrid provided alternative SKUs that met EFSA guidelines and delivered matching specs.

Case 2: Vegan Label Claim Verification

A startup needed sprinkles for a plant-based baked good. Initial supplier COAs were missing gelatin-free verification. FoodGrid matched them with a certified vegan option, avoiding costly reformulation.

Case 3: Traceability Audit Preparation

An allergen-free snack brand needed batch-level documentation ahead of a retail audit. FoodGrid delivered COAs, allergen control plans, and production lot traceability—all ahead of schedule.

MOQ Transparency and Documentation Access

Even with documentation in hand, large MOQs can prevent trial runs or scale-ups. That’s why our clean-label sprinkle program features:

- Minimum order quantity starting at 1 pallet or 2,100 lbs

- Advance access to spec sheets and COAs

- Rapid sampling timelines

Request QA-ready sprinkle samples →

The Bottom Line for QA, Regulatory & Food Safety

Clean-label trends are here to stay. But buzzwords don’t protect your brand—compliance does. If you’re responsible for verifying specs, claims, and audit readiness, FoodGrid helps you:

- Eliminate label risk

- Speed up compliance verification

- Prevent reformulation or recalls

We bridge the gap between what marketing wants and what compliance requires.

Talk to us about your QA and sourcing goals →

Clean-Label Inclusions Without the Risk

Whether you’re preparing for an audit or launching a new product line, FoodGrid gives you the visibility, traceability, and documentation you need from day one.

Explore our clean-label sprinkle options or contact us now to get started.

References

- Food Safety Magazine: https://www.food-safety.com/

- Institute of Food Technologists (IFT): https://www.ift.org/

- EFSA Food Additives Database: https://www.efsa.europa.eu/en/data-report/food-additives