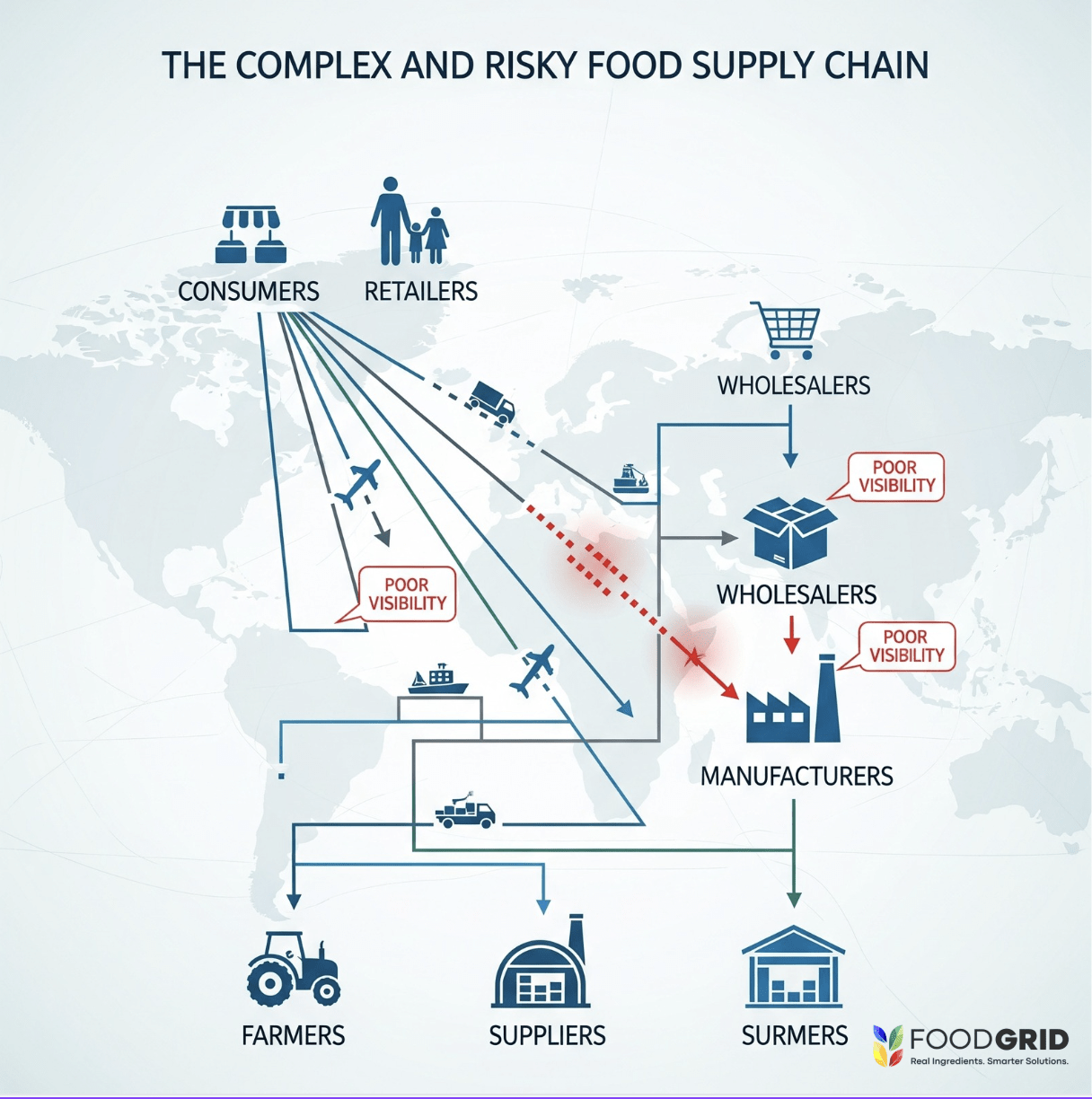

You can negotiate the best prices in the world — but if a supplier goes dark, misses specs, or triggers a recall, your margins vanish overnight. For Procurement and Sourcing professionals in the food industry, poor supplier visibility isn’t just inconvenient — it’s a direct hit to cost, risk, and compliance. This article explains the hidden costs of poor supplier visibility and what you can do to fix it before it breaks your supply chain.

1. What Is Supplier Visibility — and Why It Matters in Food

Supplier visibility refers to your ability to track supplier performance, certifications, sourcing origins, ingredient specs, shipment status, and risk factors in real-time. In food manufacturing, this means:

- Knowing whether a supplier’s certificate of analysis (COA) is current

- Tracking allergen status or contamination incidents

- Confirming supplier compliance with regulatory frameworks (e.g., FSMA, GFSI)

- Monitoring lead times, delays, and substitutions

Without this, you’re flying blind — and that’s dangerous.

🔗 Explore how FoodGrid improves procurement visibility

2. The Hidden Costs of Poor Supplier Visibility

Poor visibility doesn’t just affect your team — it disrupts every part of the operation:

❌ Production Delays

When ingredients arrive late or fail inspections, production halts. Every minute of downtime costs you labor, lost output, and missed customer commitments.

❌ Quality and Compliance Risks

If you can’t verify supplier certifications or documentation in real-time, you risk failing food safety audits or triggering recalls.

The FDA’s Recall Report showed that in 2023, over 600 food products were recalled due to undeclared allergens, many due to supply chain miscommunication.

Source: FDA Recalls Database

❌ Contract Penalties

Retailers like Walmart and Costco have strict delivery and compliance windows. Fail those, and you face chargebacks, delistings, or worse.

❌ Sourcing Bottlenecks

Ingredient buyers without real-time data spend hours chasing down COAs, certifications, and lead-time updates — instead of negotiating or optimizing cost.

3. How Procurement Buyers in Food Are Solving the Visibility Gap

Forward-thinking Procurement teams are using smarter systems to digitize and centralize supply chain data. Here’s how.

✅ Centralize Supplier Certifications & Specs

Digital supplier portals allow you to store and auto-validate:

- Organic certifications

- Allergen declarations

- Spec sheets

- HACCP plans

- Third-party audits (SQF, BRCGS, etc.)

🔗 FoodGrid’s centralized supplier compliance tools* keep your documentation current and audit-ready.*

✅ Automate Notifications for Expiring Docs

Avoid scrambling last minute. Systems with automatic alerts help you stay ahead of expiring COAs or missing GFSI certificates.

✅ Link Performance to Procurement Strategy

Connect supplier performance to sourcing decisions. Visibility into OTIF (On-Time-In-Full), rejection rates, and risk scores helps you renegotiate — or reallocate — sourcing volume.

4. Signs Your Supplier Visibility Is Failing

Even if you’re not dealing with a recall (yet), there are red flags:

| Symptom | What It Really Means |

| “We’re always chasing COAs” | Supplier documentation isn’t centralized |

| “We have no idea where the product is” | No real-time shipment visibility |

| “Audit season is chaos” | Missing or outdated supplier compliance data |

| “We were caught off guard by a spec change” | No change-control alerts or digital spec traceability |

If this sounds familiar, it’s time to modernize.

5. Real-World Consequences: When Visibility Breaks

Case 1: Allergen Contamination from a Supplier

A major food manufacturer faced a costly recall after a supplier switched ingredients without notifying QA. Peanut residue ended up in a product labeled allergen-free. It triggered a Class I recall, litigation, and loss of major retail accounts.

Case 2: Missed Delivery Windows = Millions Lost

A procurement team sourced spices from a global supplier with inconsistent documentation and long lead times. A missed shipment delayed production for a week. The result: six figures in lost revenue, emergency sourcing at higher cost, and chargebacks from two big-box retailers.

6. What Buyers Can Do: A Step-by-Step Visibility Playbook

Audit Your Supplier Data

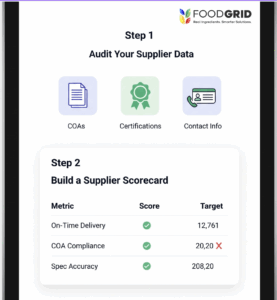

Step 1: Audit Your Supplier Data

What info is missing or outdated? Start by auditing:

- COAs

- Organic or gluten-free certifications

- Contact information

- Lead time averages

- Rejection rates

Step 2: Build a Supplier Scorecard

Track performance across key areas:

| Metric | Goal |

| On-Time Delivery | ≥ 95% |

| COA Compliance | 100% current |

| Spec Accuracy | 100% match |

| Document Responsiveness | <24 hours |

Step 3: Implement Digital Workflows

Switch from spreadsheets and emails to digital platforms that:

- Store and auto-validate documents

- Track supplier interactions

- Flag risks and trigger alerts

🔗 Learn how FoodGrid digitizes supplier interactions and traceability

Step 4: Align with QA and Operations

Make sure your Procurement, QA, and Ops teams use the same system for supplier data. This eliminates duplication and miscommunication.

Step 5: Plan for Redundancy

Never depend on a single source. Use visibility tools to identify dual-sourcing opportunities before disaster strikes.

7. What to Look For in a Supplier Visibility Platform

If you’re evaluating food procurement software, prioritize platforms that offer:

- Supplier onboarding workflows

- Real-time COA and certification tracking

- Allergen and spec documentation

- API integrations with ERP/QA systems

- Audit-ready logs and document history

- Automatic alerts for compliance gaps

FoodGrid helps procurement teams simplify supplier visibility, compliance, and risk management.

8. It’s Not About More Data — It’s About Better Decisions

Procurement professionals are being pulled into deeper supply chain strategy — especially in food. The right visibility tools help you:

- Identify reliable vs. high-risk vendors

- Renegotiate contracts based on performance

- Maintain audit readiness with QA

- Source smarter and faster in tight markets

Visibility isn’t overhead. It’s leverage.

Ready to reduce sourcing risk and take control of your supplier visibility?

Schedule a demo of FoodGrid and see how we help Procurement teams digitize supplier compliance, traceability, and risk — all in one platform built for food manufacturing.

References (All links verified, non-competitor)

- FDA – Recalls, Market Withdrawals, & Safety Alerts

- CDC – Food Safety for Industry and Professionals

- USDA – Supply Chain Resilience Strategy

- World Bank – Agriculture and Food